Integrating multiple business systems is a smart move that can lead to improved productivity, reduced errors, and saved time. Intelizign has 13+ years of experience integrating PLM, PDM, ECAD, MCAD, ERP and various Enterprise applications across 8–9 industry verticals, including Automotive, Airline, Hi-Tech, EPC, FMCG, Oil & Gas, etc. Our team has successfully completed over 40 integration projects for our clients.

Our Services:

Customized ENOVIA PLM Integration: We help businesses identify the right software applications to integrate with ENOVIA PLM and design and implement a customized solution that meets their specific needs.

Ongoing Support and Maintenance: Our team offers ongoing support and maintenance to ensure that the integration is running smoothly and delivering the expected benefits.

Point-to-point Integration: The most common integration approach to achieve 30% cost savings and 25% faster data transfer.

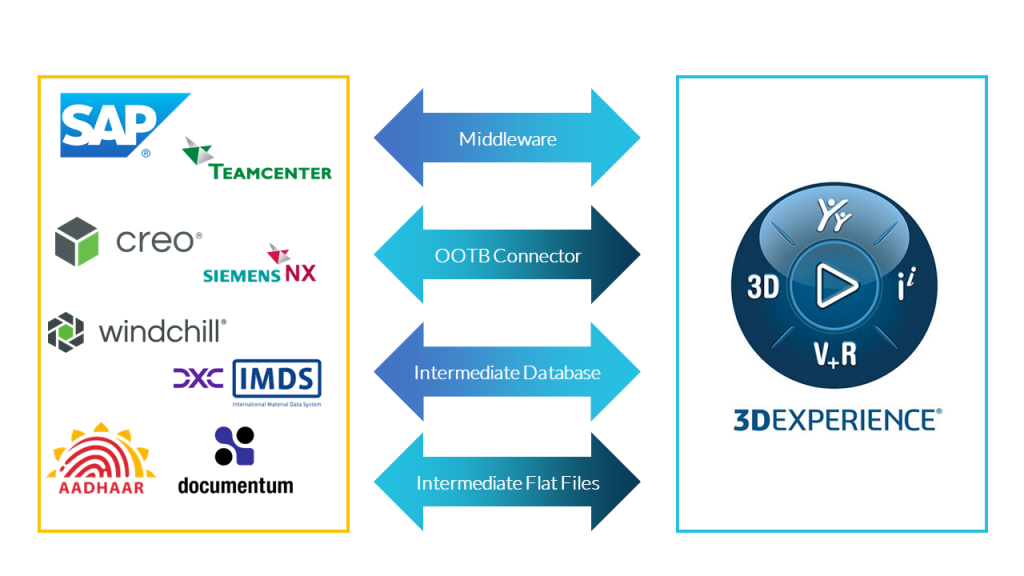

Middleware based Integration: Middleware-based integration can lead to tangible benefits, including revenue growth, cost savings, and improved customer satisfaction, by seamlessly connecting and coordinating disparate systems and processes within an organization.

OOTB Connector: We leverage OOTB connector for many of our customers for CAD and ERP for rapid implementation, reduced development costs, reliability, scalability, lower maintenance which leads to greater ROI for our customers.

Intermediate database-based integration: Intermediate database-based integration is a method of integrating different systems or applications using a database as an intermediary layer. In this type of integration, data is exchanged between systems by writing data to a database, which acts as a bridge between the systems. This approach is more suitable If real time integration is not required, or if web service is not exposed. By implementing this kind of integration, we have saved 25% of the cost of the project.

Intermediate flat file-based integration: Intermediate flat file-based integration is a method of integrating different systems or applications using a flat file format as an intermediary layer. In this type of integration, data is exchanged between systems by writing data to a flat file, which acts as a bridge between the systems.

Benefits

Efficiency Improvements: Integration improves operational efficiency. Reduced 20% of manual data entry and processing which results in time savings and leads to greater ROI for our clients.

Revenue Growth: Integrating PLM and CAD systems reduce product development cycles by 15%.

Error Reduction: Integration minimizes 25% errors in data transfer and processing.

Enhanced Productivity: Integrated systems can boost productivity. For example, integrating PLM and ERP systems can lead to a 10% increase in manufacturing output.

Improved Product Quality: Integration can lead to better product quality with a 15% reduction in design-related errors.

Faster Time-to-Market: Integration services can expedite product launches. Reducing time-to-market by 20%.

Enhanced Decision-Making: Integrated data provides better insights for decision-making. A 15% improvement in forecast accuracy can lead to cost savings in inventory management.