With increasing pressure to bring innovative, lower-cost products to market faster, manufacturers are trying to improve efficiency of their concurrent engineering, manufacturing and production processes. This requires a solution where before products are completely designed, much of the production process (including Production Engineering, Production Planning and Production) can be described, laid out and if possible, validated. Executed in a digital environment, this significantly improves productivity and allows multiple product programs to be managed under a single source of information in full association with product design, manufacturing planning and production requirements.

Today’s manufacturers face increasingly shortened development schedules. They need to get as much out of their existing resources as possible. Searching for information, creating production plans from scratch and handling constant change causes productivity to suffer and have the risk of:

- Delayed market delivery.

- Unanticipated costs.

- Lost revenue opportunities.

- Sub-optimized production.

- Non-optimized Inventory management

SIEMENS Teamcenter software

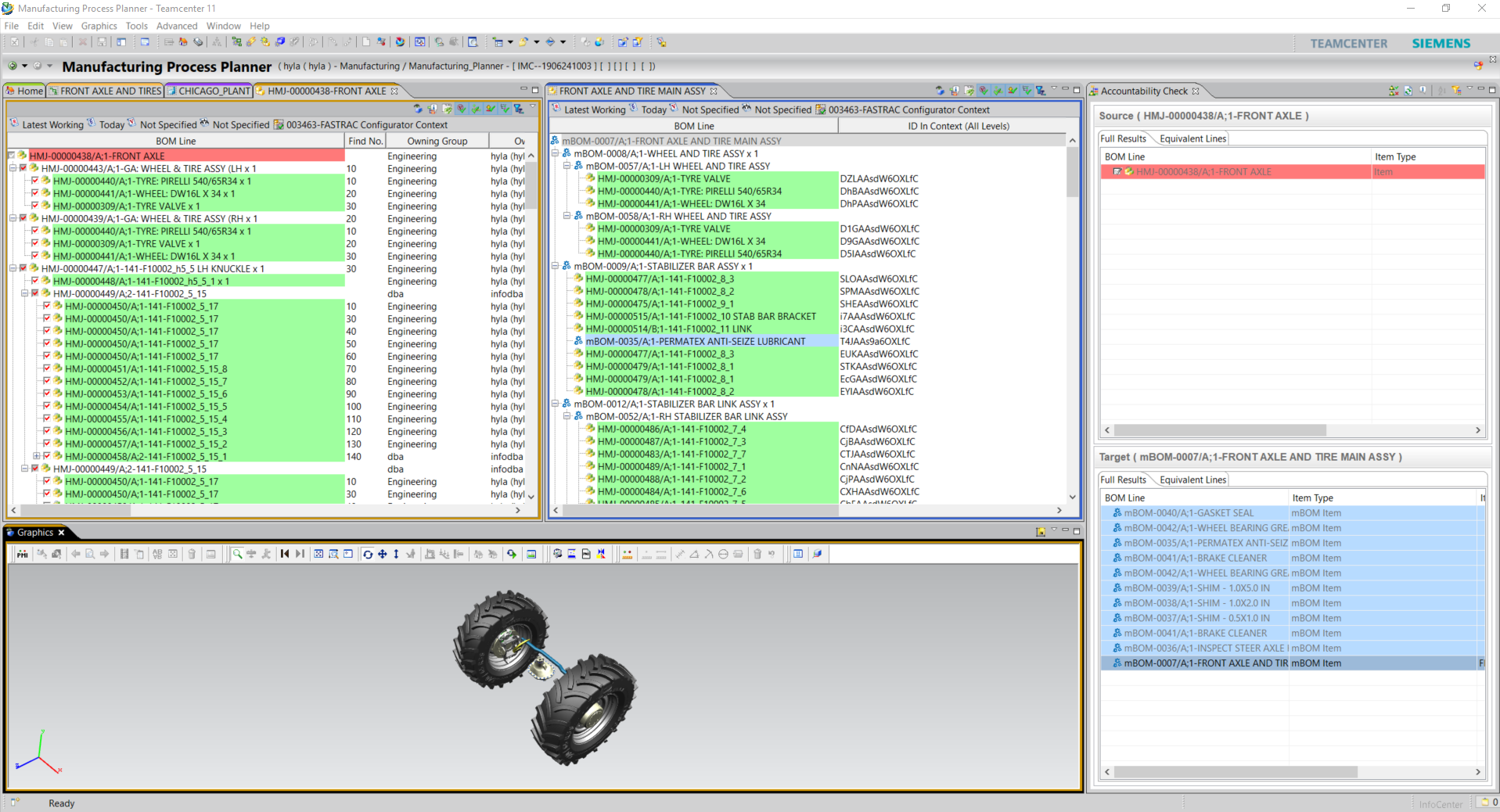

SIEMENS Teamcenter software’s capabilities for Manufacturing Data Management enable customers to collaboratively create, validate and optimize manufacturing plans concurrently with product design. By providing a common environment for multiple disciplines that share the same requirements, Teamcenter drastically improves lifecycle productivity between engineering, manufacturing and production. This reduces wastages (which can be quite significant depending on the kind of industry) and increases decision value as information interrelationships are leveraged by a broader audience to arrive at better decisions in a shorter amount of time.

Many of the long-term benefits from product lifecycle management (PLM) cannot be achieved without a comprehensive digital manufacturing strategy. Digital manufacturing is a key point of integration between PLM and various shop floor applications and equipment, enabling the exchange of product-related information between design and manufacturing groups. This alignment allows manufacturing companies to achieve their time-to-market and volume goals, as well as realize cost savings by reducing expensive downstream changes.

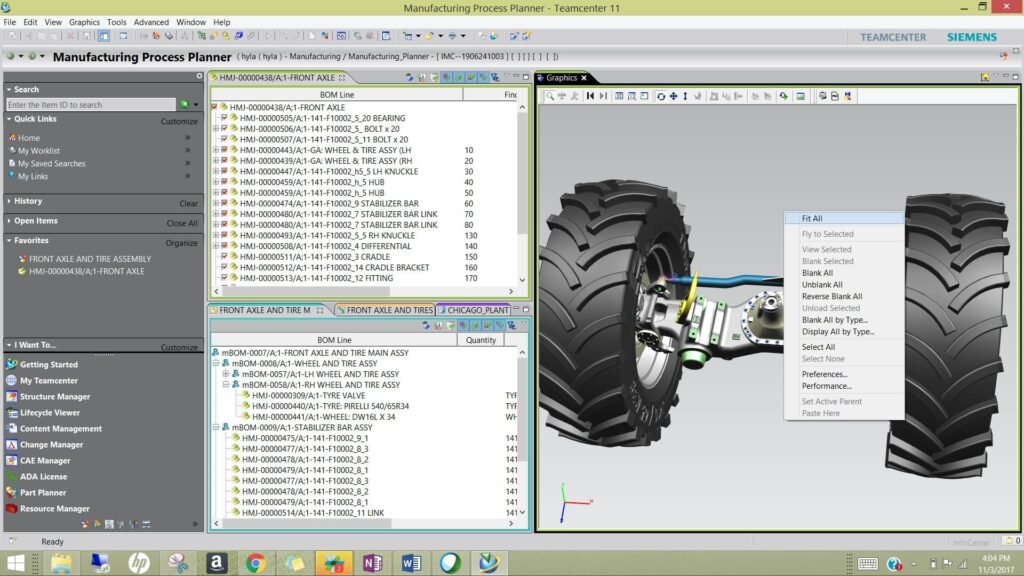

Teamcenter allows manufacturing engineers to create the complete definition of a manufacturing process in a virtual environment, including:

- Tooling

- Assembly Lines (including inner processes)

- Work Centers

- Facility Layout

- Resources

Benefits

- We have done quite a number of successful implementations across the globe.

- We have transcended the different boundaries right from Engineering Bill of Material (EBOM), Manufacturing Bill of Material (MBOM), Bill of process (BOP) that is traceable through Engineering Change Process(es).

- In the context of Manufacturing process, we have successfully been able to capture and Manage manufacturing data, process, resource and plant information in the same single environment that you use to manage your product data.

- Supports Industrial Standard Methods-Time Measurement(MTM) way of Time analysis.

- Ability to identify the bottle-neck Stations on Assembly line using Line Balancing feature.

- Ability to produce flexible work instructions capable of displaying 2D/3D part information, along with the machining and tooling instructions. Fully implemented Line Balancing features have enabled customers to easily identify ‘bottle-neck’ stations.

- Teamcenter facilitates accountability and reconciliation between plant, process, resource and product configurations and collectively supports real-time enforced consistency & reconciliation as the product lifecycle evolves.

- Enabling users to view and validate re-use of costly production assets across multiple product programs.

- Teamcenter open architecture provides the most flexible solution on the market for sharing of information between a wide variety of digital manufacturing and shop floor systems.

- Teamcenter tight integration with Tecnomatix software enables your PLM environment to leverage data generated by best-in-class digital manufacturing solutions that run the gamut from manufacturing engineering to shop floor execution.

- Manufacturing resource visibility: Teamcenter provides a unique classification scheme that enables you to manage virtually any manufacturing resource from tooling and machinery to best-in-class process plans and shop floor layouts.

Intelizign Advantage

Our consultants work closely with your teams to incorporate your manufacturing process management requirements in alignment with your business processes.

5+ projects implementation with complete ownership of End to End Teamcenter Manufacturing Process implementation.

- Done it for more than 40 Business Units

- Moved from Legacy/Excel systems into TcManufacturing platform

- Customers were able to realize a benefit for about 30% through our implementation.

10+ years of Expertise in PLM and Manufacturing Data Management.

- A strong team of more than 30 personnel who bring both functional and technical knowhow to the customers.

Extensive experience with EBOM – MBOM Alignment, Reconciliations, Bill of Process, Time Calculations and Manufacturing Reporting implementations.

Aligned with Industry best practices in implementing these solutions.

- Through our accelerated implementation, we have been able to impart Industry best practices to our customers.

Ready customer references.

- Will be provided on demand.