For every company Suppliers are becoming an integral part of the business and product delivery process. Rather producing everything in-house, companies have recognized the potential of leveraging external resources where they are no more constrained to have the expertise internally. Managing all the touch points with suppliers in a coordinated manner is a growing challenge and addressed comprehensively by Teamcenter Supplier Collaboration Framework (SCF).

Teamcenter’s Supplier Collaboration Framework supports the following four use cases:

DESIGN DATA EXCHANGE

- Design data exchange that is integrated with Teamcenter processes.

- Facilitate authorized suppliers to access design data directly from Teamcenter.

SUPPLIER PROGRAM MANAGEMENT

- Initiate data sharing from task workflows.

- Share prerequisite task data with suppliers.

- Collect task deliverables from suppliers.

DIRECT MATERIALS SOURCING

- Provide end-to-end integrated sourcing.

- Enable authorized bidders to access product data directly from Teamcenter.

- Provide robust sourcing capabilities.

SUPPLIER SUBSTANCE DECLARATIONS

- Automate supplier material and substance declaration processes.

- Aggregate material data from suppliers to the product structure.

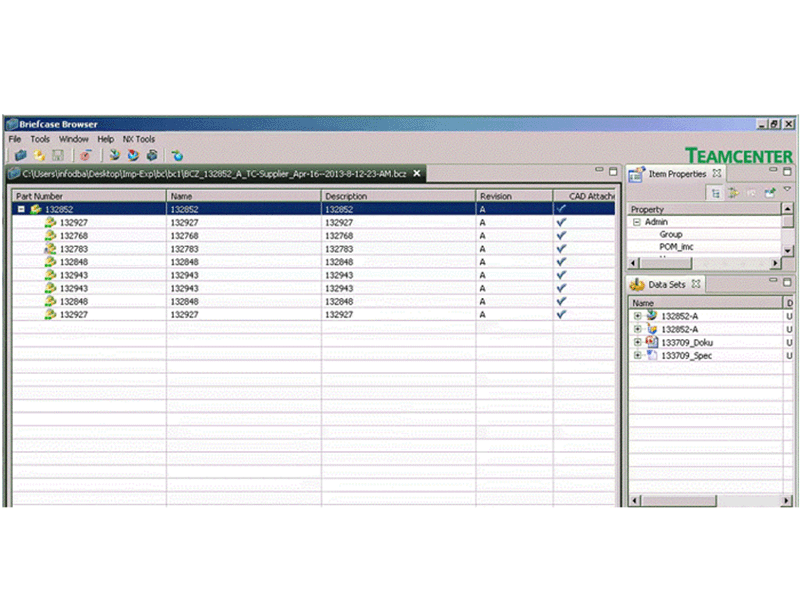

Siemens also provide a lightweight standalone tool for enabling suppliers to work offline on OEM design packages called Briefcase Browser. Briefcase Browser is an easy to- use tool for suppliers that do not have Teamcenter. The browser can run on a supplier’s desktop and provides the ability to:

- Read a briefcase, including structure, items, attachments and properties.

- Launch the CAD portion of the briefcase to NX™ software or a CAD-neutral JT view.

- Update, or create a new briefcase containing NX files that can be consumed using the OEM’s Teamcenter.

Supplier Collaboration / SRM Integration

Benefits

- Increase productivity and shorten new product development time by including your supply chain early in the design process and thus reduce.

- Simplify the complexity of managing an extended supply chain.

- Register new suppliers to evaluate capability and include in future design and sourcing events.

- Reduce risk with traceability of supplier information managed in the context of your product BOM.

- Improve the accuracy of offline supplier deliverables by ensuring version alignment and control.

- Reduce rework costs with closed-loop integrated processes including the offline supply chain.

- Increase visibility by enabling analysis, design reviews and decision making for the entire product.

- Briefcase Browser enables OEMs to efficiently share CAD design data with suppliers who do not have Teamcenter and Lowers costs to the supplier base by providing a low install, low overhead tool for CAD design data sharing.

Intelizign Advantage

A group of Functional and Technical experts in the domain of CAE & Simulation Data Management work with the customer SMEs to identify the key data points and processes that best suit your organizations Simulation Data Management requirements. Some of the key highlights of Intelizign’s expertise in Simulation Data Management domain are as enlisted below.

- 5+ Projects designed and implemented using Teamcenter Supplier Integration solutions.

- Executed Upgrade Projects for moving old Supplier Collaboration to the new Supplier Collaboration framework.

- Experience in Configuration and Customization of Briefcase Browser.

- 10+ years of Expertise in PLM, ERP and Enterprise Application Integrations.

- Aligned with Industry best practices in implementing these solutions.

- Cost effective with right-shore approach.

- Ready customer references.